◆ Suitable for positioning and non-positioning labeling of round bottles, bottom or side positioning.

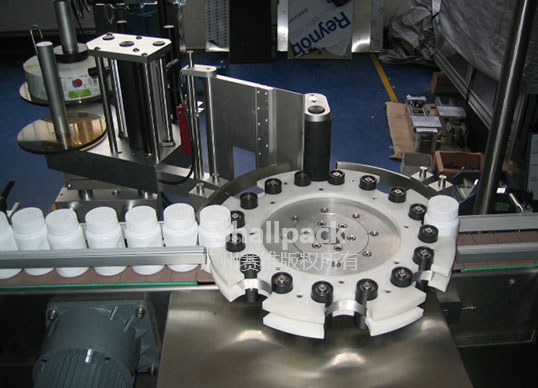

◆ Roulette type feeding, high-precision cam divider drive, 8 stations operation.

◆ Servo motor drive, realizing true closed-loop control, high-precision subdivision, built-in absolute encoder, meeting high-speed and high-precision positioning.

◆ The label output head adopts a double pressing roller structure to ensure that the label is tightened and avoid label breakage caused by die-cutting damage to the bottom paper. The segmented clutch makes the tension more balanced.

◆ The six-dimensional space adjustment of the header, powerful and flexible adjustment ability, accurate labeling of any product can be adjusted within a few minutes.

◆ Advanced and friendly man-machine interface system, operating parameters can be stored and recalled, fault prompts and help information, the operation is simple and easy to learn, and workers can operate with a little training.

Labeling speed: up to 150 pieces/min

Labeling accuracy: ±1mm

Attached object size: φ15-φ100mm

Maximum label width: 200mm

Applicable paper roll Inner diameter: φ76mm

Applicable paper roll outer diameter: φ380mm

Machine size (LxWxH): L2000XD1200XH1600mm

Power consumption: 220V 50Hz 1500W

Rotary round bottle labeling machine

Copyright(C)Guangzhou Shallpack Equipment Co., Ltd.