1. This machine is suitable for multi-sided labeling on the top, bottom and sides of flat products, using roll labels.

2. The labeling head adopts the high-precision servo motor of a famous factory to control the labeling

3. The control system adopts Siemens PLC, equipped with famous factory touch screen, bilingual operation interface in Chinese and English.

4. The labeling head is easy to adjust, and the labeling speed and conveying speed can be tracked synchronously.

5. The unique entrainment structure ensures stable and accurate labeling of products.

6. Conveyor line speed, belt pressing speed and label output speed can all be set and controlled on the touch screen.

7. LRD6100 label sensor is optional, suitable for all roll-type self-adhesive labels.

Marking speed: up to 30 m/min

Labeling accuracy: ±1mm

Maximum label width: 100mm

Applicable label roll inner diameter: 76mm

Applicable label roll diameter: maximum φ300mm

Machine size: 1500X800Xφ1800(mm)

Power consumption: 220V 50Hz 2000W

/

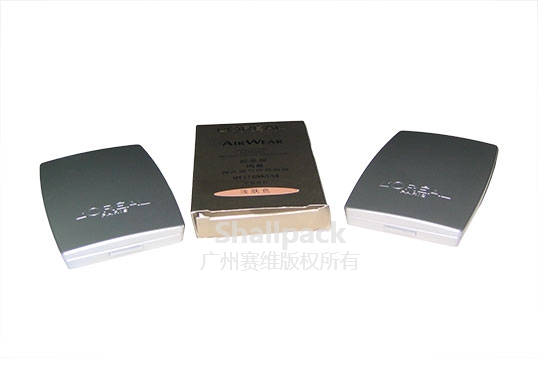

top and bottom labeling machine

It is suitable for the top and bottom labeling of flat products. The perfect design of the whole machine, high-performance control, detection and rejection system ensures fast and accurate labeling, unique instant coding and labeling function, and defective products such as wrong and no labels. Detection and rejection functions.

Copyright(C)Guangzhou Shallpack Equipment Co., Ltd.